AC motor

uses brushless electric currents to turn back on a regular basis over a period of time. The electric motor has two basic elements of power: "stator" and "rotor" as shown in Figure 7 daalam. Stator is a component of static electricity. The rotor is rotating electrical components to operate the motor. The main advantage of AC motor DC motor is that speed AC motor more difficult to control. To overcome this drawback, AC motors can be equipped with variable frequency drives to improve speed and lower power control. induction motor industry is the most popular cycling because of the reliability and easy maintenance. AC motor induction is very cheap (half price or less than the price of a DC motor) and also gives a relationship between power and weight is very high (about twice the DC motor).

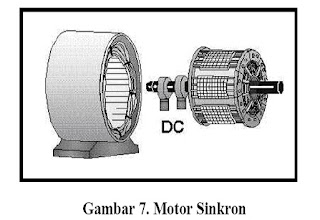

synchronous AC motor

Synchronous motor synchronous motor is an AC motor operating at fixed speed at a specific frequency. These engines require the production of electricity in direct current (DC) and the first pair of low, suited to a synchronous motor from use with small loads such as air compressors, generators and changes frequency of the motor. Synchronous motor capable of improving the power factor of the system, so often used in systems using much power. Electrical Energy Equipment: Electric Motors This motor rotates at synchronous speed is given by the formula Ns = 120 F / P Where: f = frequency of delivery frequency P = number of poles

Industrial Automation Related Post :

1.Industrial Electric DC Motor Types

2.Industrial Electric DC motors

3.Industrial Electric Motor

4.Industrial Automation